AGGREGATE IS A GRAININESS MATERIAL WHICH IS USED AS SKELETON OR FILLER IN THE CONCRETE

AS THE MAIN MATERIAL OF CONCRETE

AGGREGATE IS ALSO SKELETON AND BRACE OF BUILDING

WHAT IS AGGREGATE

Construction engineering, water conservancy, bridge engineering and highway engineering, you can see aggregate anywhere.

COARSE AGGREGATE:

Coarse aggregate whose size is more than 4.75 mm is also called stone. Coarse aggregate contains gravel and pebble. Gravel is formed from crushed natural rock, but pebble is formed from accumulation caused by weathering, river transportation and accumulating.

FINE AGGREGATE:

Fine aggregate whose size is less than 4.75 mm is also called sand. According to different sources, fine aggregate contains natural sand and artificial sand. Natural sand is formed from rock particles caused by weathering and river transportation, but artificial sand is a general term for machine-made sand and mixed sand.

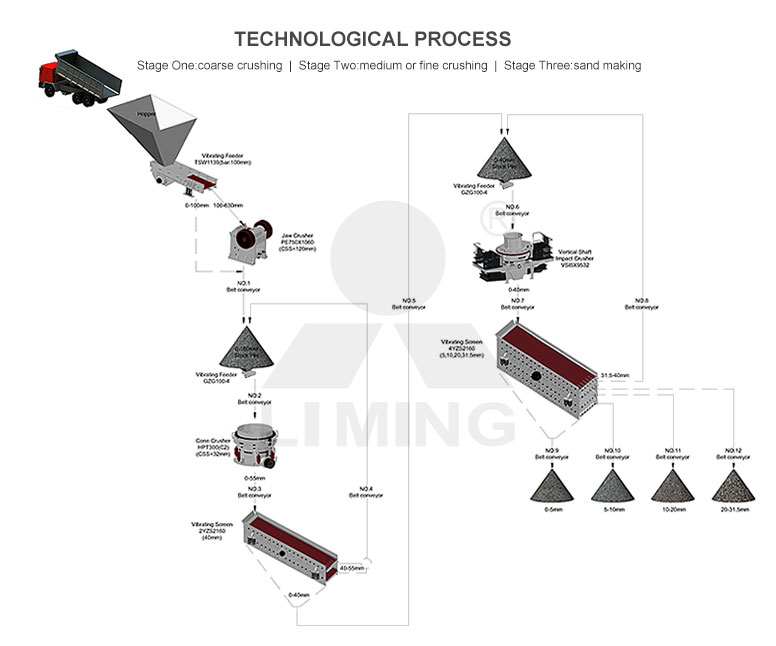

STAGE ONE: COARSE CRUSHING

Vibrating feeder sends big materials from storage bin to jaw crusher for coarse crushing. After primary crushing and screening, belt conveyor sends materials to impact crusher or cone crusher for medium or fine crushing.

STAGE TWO:MEDIUM OR FINE CRUSHING

Materials are crushed secondarily by impact crusher or cone crusher and then sent to vibrating screen for screening. Some big materials will be sent to impact crusher or cone crusher for reprocessing if the sizes are unqualified.

STAGE THREE:SAND MAKING

Crushed materials will be sent to sand making machine for crushing and shaping. And then they can be sent to sand washing machine if you need clean materials.

140TPH Sand Making Project in Vietnam

Equipment:Jaw crusher PE500X750, cone crusher HPT220, sand making machine VSI5X9532, sand washing machine XSD3016, two sets of vibrating screen 4YZS1848

Material:Limestone

Capacity:140T/H

Input size:0-30mm

Output size:0-4.5mm

This project is a sand making project in Vietnam. We recommend this plant with HPT200 and VSI5X9532 to customer according to usage of final products. This plant is designed to offer high quality aggregate to projects like highway construction, high-rise building construction.

300-400TPH Iron Mining Project in Copiapo, Chile

Equipment:Four sets of sand making machine VSI5X1145, jaw crusher PE900X1200, cone crusher CSB240 and vibrating screen 3YZS2160

Material:Iron ore

Capacity:300-400T/H

Input size:0-750mm

Output size:0-6mm

Our engineer designed a flowchart with PE series jaw crusher, CS series cone crusher and VSI5X series sand making machines. PE jaw crusher can process big iron ore, and CS series cone crusher shows its strength of lamination crushing theory and makes final products epigranular,

C6X Series Jaw Crusher

Adopting advanced crushing technology, C6X Series Jaw Crusher can crush hard materials roughly. With the design of optimized crushing chamber, double wedge adjusting device, elastic limit damping device and integrative motor cabinet, it takes advantages of high efficiency, low investment costs and superior performance

VSI6X Impact Crusher

VSI6X Sand Making Machine is used for shaping aggregate. This patented machine adopts new impeller structure with four openings and special seal structure which prevents bearing from leaking oil. It takes advantages of energy-efficient, long service life and wide applications

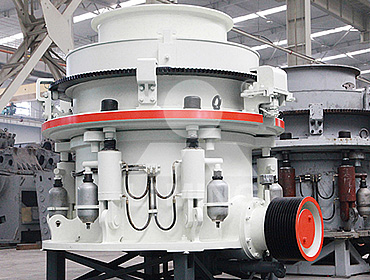

HPT Cone Crusher

HPT Hydraulic Cone Crusher is used for medium or fine crushing in aggregate crushing line, and it usually crushes hard materials because of large capacity and strong crushing strength. Due to the specific between-layer pressuring crushing principle, the rate of cube-shaped final products is improved and needle-like particles are reduced

Efficient crushing equipment

Based on advanced production base with 300, 000 m², LIMING produced high-end equipment constantly. Because of mature technology, stable performance and reliable quality, the company has won many trusts and praises from 130 countries.

Professional technical team

From on-the-spot investigation, conceptual design to model selection and installation, project manager conducts the whole work about aggregate crushing line prudentially. He will solve technical difficulties during the project and remove customers’ worries effectively.

Wholehearted service concept

Giving clearly solutions in 24 hours, arriving customer site in 48 hours and solving the fault absolutely in 72 hours, we always persist in principles about standardization, valuation, serialization and differentiation. Besides, we give first priority to quality and provide valuable products and services for customers.