Granite Crusher

Granite crusher is the stone crushing machine used for crushing granite rocks into small particles for building aggregates production and crushed fine granite for sand production.

The processing is easy to understand. After being screened by the steel grid of the vibrating feeder, the small size materials will be dropped to the belt conveyor. Then the materials with qualified sizes will be evenly sent into the Jaw Crusher for the primary crushing. After being crushed by Jaw Crusher, the finished products will be transferred to the storage yard under which there is a hopper installed by belt conveyor, after being dropped to vibrating feeder from the hopper, the outputs will be sent into cone crusher via belt conveyor for secondary crushing. After secondary crushing, those materials were sent to circular vibrating screen for screening out the products that could be transported to sand making machine, the unqualified products were sent to cone crusher for re-crushing, and the qualified products were transferred to sand making machine for reshaping via belt conveyor, after reshaping, the finished products were sent to circular vibrating screen for screening out the required products.

Final products size: 0-40mm

Capacity: 500-600tph

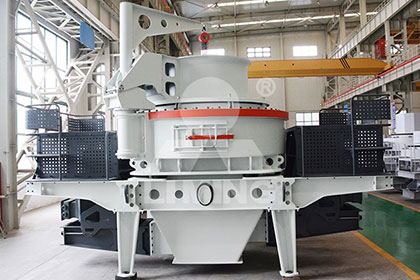

Equipment: Vibrating Feeder GZD1500×6000, Vibrating Feeder GZG100-4, PE Series Jaw Crusher PE1200×1500, HST Series Single Cylinder Hydraulic Cone Crusher HST250/S2, VSI Sand Making Machine VSI1140, Vibrating Screen 2YZS2160, Vibrating Screen 3YZS2460

Mineral Crusher

Mineral Crusher